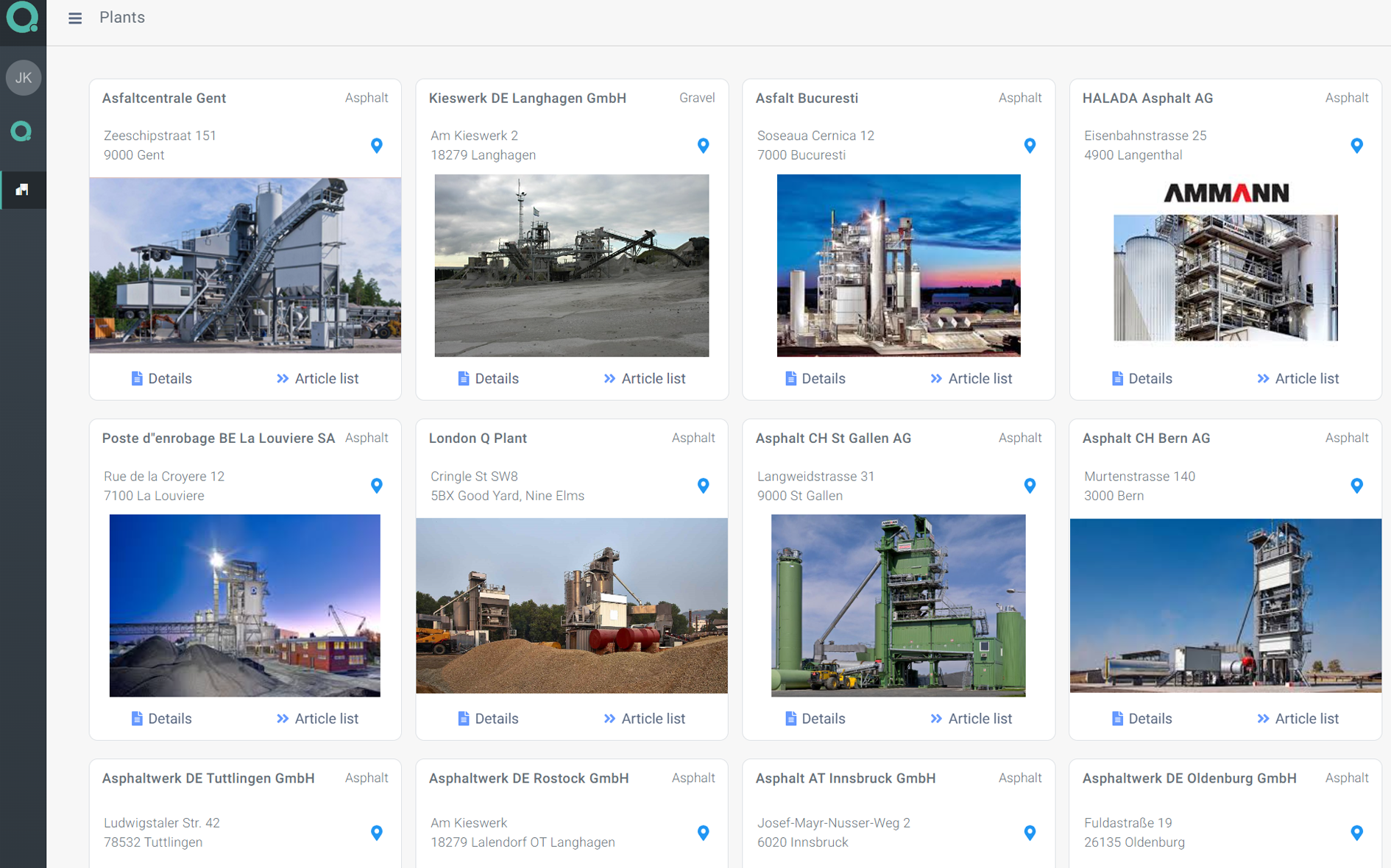

Q Plant is a comprehensive application for operators of mixing plants that can integrate all relevant information from plant control, weighing systems, laboratory programs, CRM, and order management into a single platform. This cloud-based web solution offers, depending on the edition, access to all important data such as plant and production data, customer orders, delivery and production status, operation times, delivery notes, reports, batch protocols, energy consumption, and much more, anytime, and anywhere.

The solution is divided into editions, allowing it to grow with the individual maturity level of the company and be modularly expanded to meet the company's needs.

The entry-level solution for mixing plant optimization. The digital ordering and delivery process is the focus as a basis for optimizing the production sequence.

Offers additional comprehensive integration options to incorporate the application into the IT infrastructure of the company. With this edition, a holistic digital process can be realized.

It enables the analysis and comparison of operational and production data from different mixing plants in conjunction with plant control systems.

They can be customized to match the editions. They include solutions for integrating plant control and advanced dashboards.

PRODUCT COMPONENT

Q Plant web portal

This web portal enables access to all information about the mixing plant using an internet browser. The order management, which includes the digital ordering and delivery process, can be handled completely digitally. Plant and production data, other documents as well as sub-harmful dashboards are also available, depending on the respective expansion stage.

Produktkomponente

Kundenportal

This web access enables the customer to access delivery notes and, if applicable, invoices digitally at any time. The documents will be automatically transferred to the portal and made available there. An additional service for mixing plant customers.

PRODUCT COMPONENT

Q Site Entry

Each Q Plant license includes the option to provide its customers with a digital ordering solution. This solution can be used by mobile (with the SiteBuddy App) or with an Internet browser for the digital ordering and delivery process. The customer can only use these functions in connection with the licensee of Q Plant.

PRODUCT COMPONENT

TruckBuddy App

Each Q Plant license enables truck drivers to be integrated into the digital process free of charge using the TruckBuddy App. The driver receives a digital transport order in the form of a delivery note on his smartphone and continuously communicates the current position with the plant during the transport.

PRODUCT COMPONENT

Q Directories

The business directory is the work directory for suppliers, with which they present their locations online for their customers. Informations are published here, such as contact details, opening times and, above all, the articles on offer including the associated documents. Q Directories forms the basis for all digital order systems in the digital order and delivery process.

Your Language, Your Choice

Our software is available in German, English, French, Spanish, and Romanian to optimally support our international customers. Flexibility and user-friendliness are at the forefront. Do you need another language? No problem! Order-related implementations are possible at any time.

Having the ability to exchange information along the entire supply chain digitally ensures that everyone is on the same page. More transparency enables effective and cost-efficient processes.

Bernhard Kunz

CEO