Road construction, often seen as conservative, is increasingly embracing digitalization. This is particularly evident in the asphalt paving process, where the potential of digital technologies is becoming more apparent. This field is characterized by its complexity and the need for close collaboration among numerous stakeholders.

A well-coordinated team is a crucial factor for the success and achievement of a project. Traditionally, two central figures are at the heart of the asphalt paving process: the site foreman and the weighmaster at the mixing plant. Both play a key role in orchestrating and coordinating activities, both in preparation and especially during the actual asphalt paving.

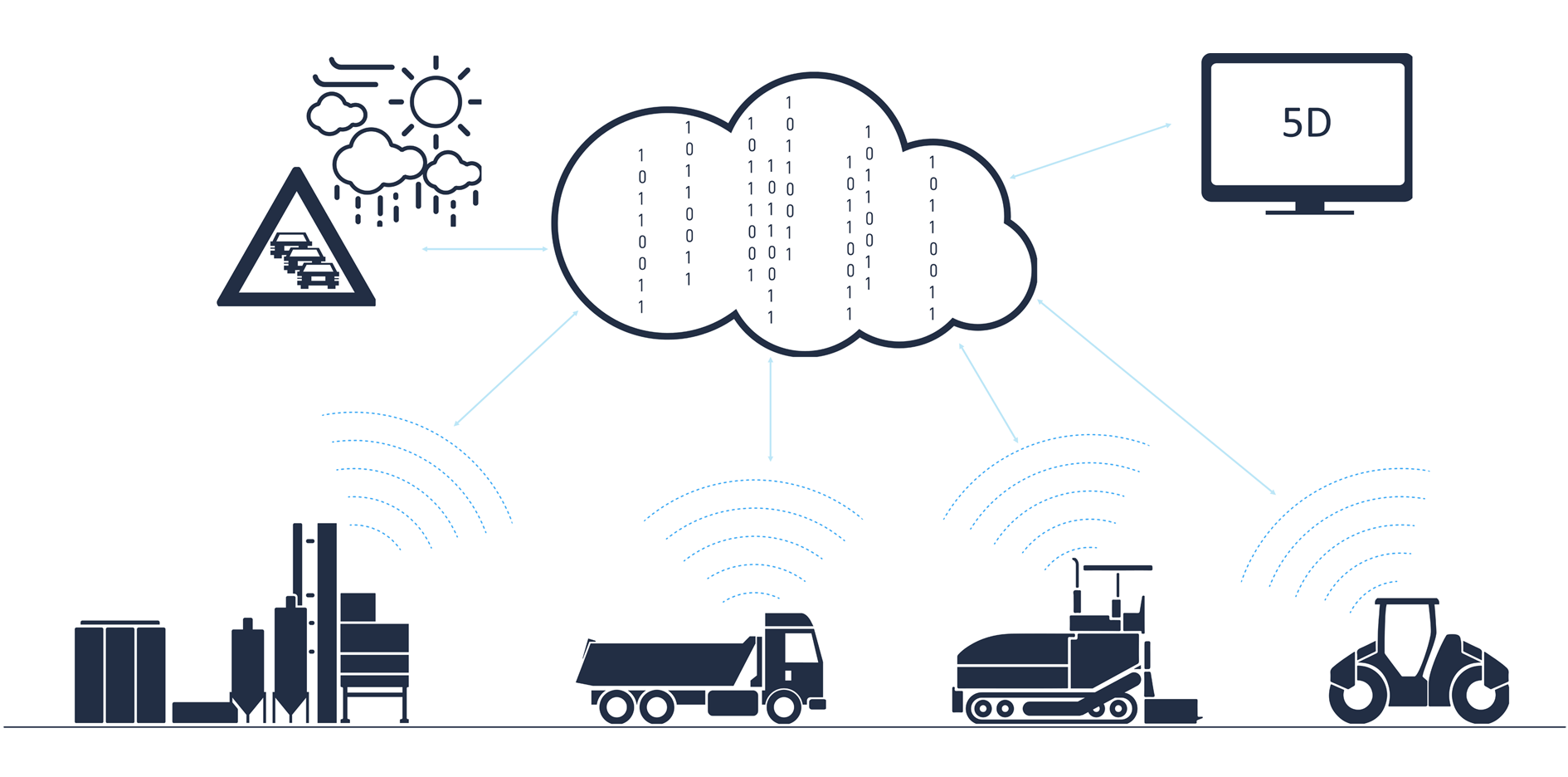

Traditionally, coordination between the site and the mixing plant relies mainly on phone calls and personal agreements, which can lead to risks of information loss and misunderstandings. In contrast, digitalization allows for direct, error-free information exchange. It ensures access to decision-relevant data and promotes transparency and efficiency across company boundaries. Digitalization forms the foundation of a connected road construction site, paving the way for a digitized, transparent, and optimized construction process.

Exemplary Workflow of a Connected Asphalt Construction Site

The progress in the digitalization of road construction is leading to a significant transformation: construction sites are no longer isolated work sites but digital nodes within an extensive process network. An exemplary workflow of such a connected asphalt construction site illustrates the scope of this development.

Software providers like Q Point specialize in driving this change forward. With applications such as "Q Site", they offer tailored process support for road construction companies. This software solution enables all stakeholders in asphalt paving to support each step precisely and efficiently. The digital support extends from paving planning, and the coordination of resources and material quantities, to ongoing process monitoring, and comprehensive documentation of all relevant activities and workflows. Through digital networking, decision-relevant information can be exchanged promptly among the involved parties. This leads to greater agility and reduced downtime overall.

The following sections will explore the practical application of a digitally connected construction site and the resulting benefits at each phase of the construction process.

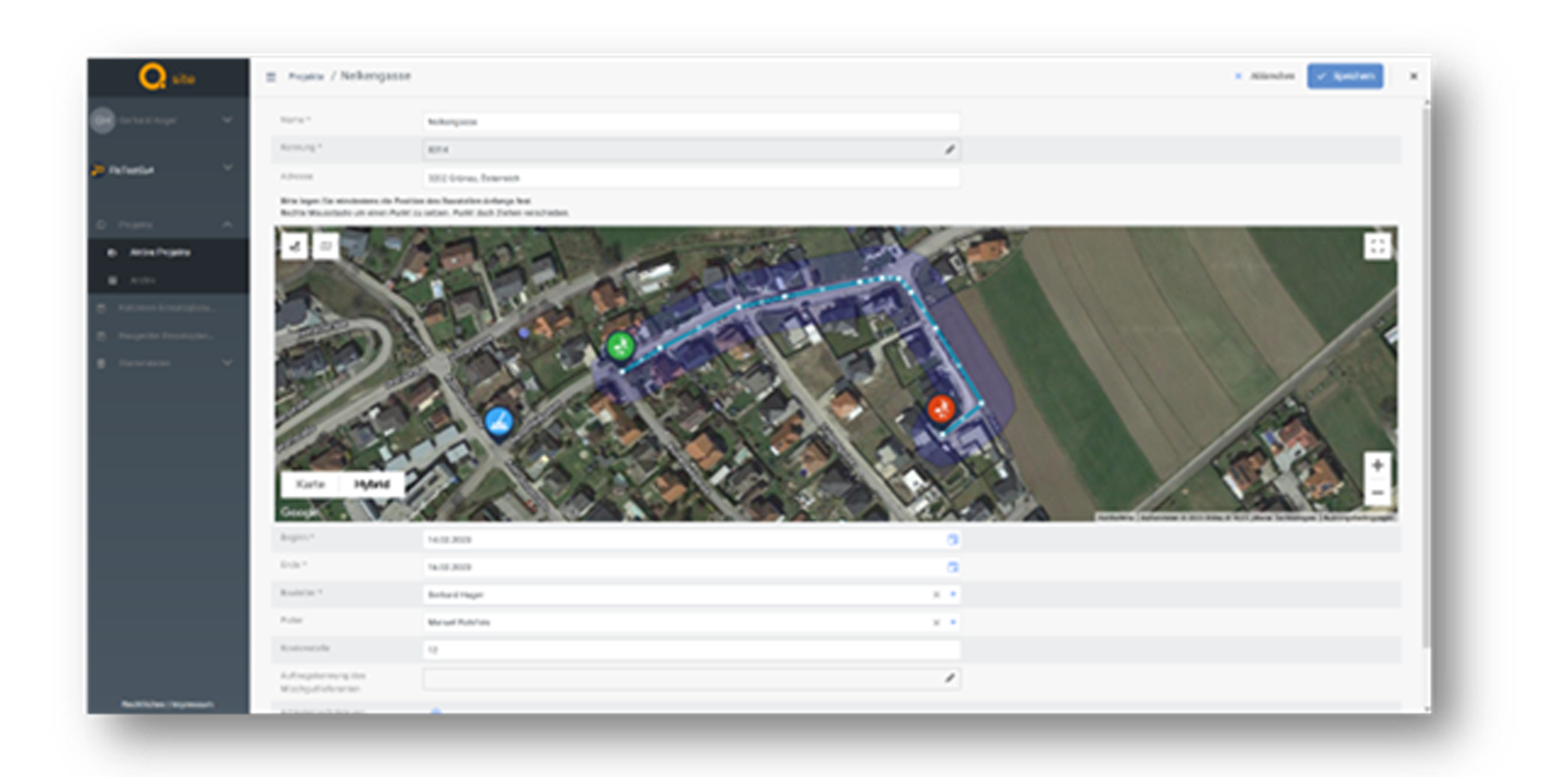

Geometry and Layer Planning

The first planning step in an asphalt paving project involves geometry and layer planning. This includes the precise definition of the geometry of the asphalt layers to be created, as well as the calculation of the required quantities of mix. The specifications are determined either based on an imported overlay book or by measuring construction plans in PDF format. For all methods, the construction process support software provides efficient editors that enable precise planning.

Once the volume bodies are defined, the type of asphalt mix is determined. This selection is typically based on the requirements of the underlying framework contract and the online product catalog of the supplying asphalt plant. The digital query eliminates redundant data collection and prevents errors or misunderstandings in the material procurement process.

With the determination of the asphalt mix type, the site manager also gains access to a wealth of data on technical material properties and related documents, such as the initial test report of the material. The otherwise time-consuming task of acquiring information and documents is streamlined through this digital networking. Digital product catalogs and online directories, such as "Q Directories" by Q Point, serve as the basis for this exchange. They provide a centralized and instantly available source of information, facilitating efficient planning and informed decision-making.

Logistics Planning

In the context of logistics planning, the transport routes between the mixing plant and the construction site are determined. This involves establishing the routes for both outbound and return trips to ensure optimal travel distances.

Based on the travel time or planned turnaround time and the delivery requirements of the construction site, the need for trucks and the scheduling of their deployment are calculated. This planning step is crucial for ensuring a consistent and adequate material flow that meets the project requirements. The resulting data on truck needs and deployment times are transmitted digitally to the responsible transportation service provider.

Deployment Planning of Construction Machinery

In the deployment planning of construction machinery, the site manager specifies the construction equipment, pavers, and rollers required for the paving work. The specific requirements for types of equipment are then communicated to the dispatcher or a rental service.

Asphalt Mix Orders

These orders or requests include all essential information for the delivery of the asphalt mix. This includes precise details regarding the type and quantity of the mix, as well as the planned delivery time. It also covers logistical parameters for transport to the construction site. Additionally, general information such as contact details of the site manager, the foreman, and specifics for subsequent performance invoicing is provided.

The digital exchange of data between the construction company and the asphalt plants also includes a binding confirmation of the orders. The existing network ensures that all necessary information and agreements are documented without requiring direct contact or phone calls. This precise and comprehensive documentation guarantees a high level of process reliability and minimizes the risk of errors and misunderstandings before the actual paving begins.

Support for the Ordering and Production Process at the Asphalt Plant

Software solutions such as "Q Plant" by Q Point act as a digital hub for the asphalt plant. On one hand, it facilitates order management by handling most transactions digitally with customers. On the other hand, it supports the associated production, preparation, and delivery of the asphalt mix.

The available order data forms the basis for generating a production plan. Using artificial intelligence, the plant supervisor receives optimized solutions that consider strategic goals such as timely delivery and efficient resource use.

Execution of Asphalt Paving

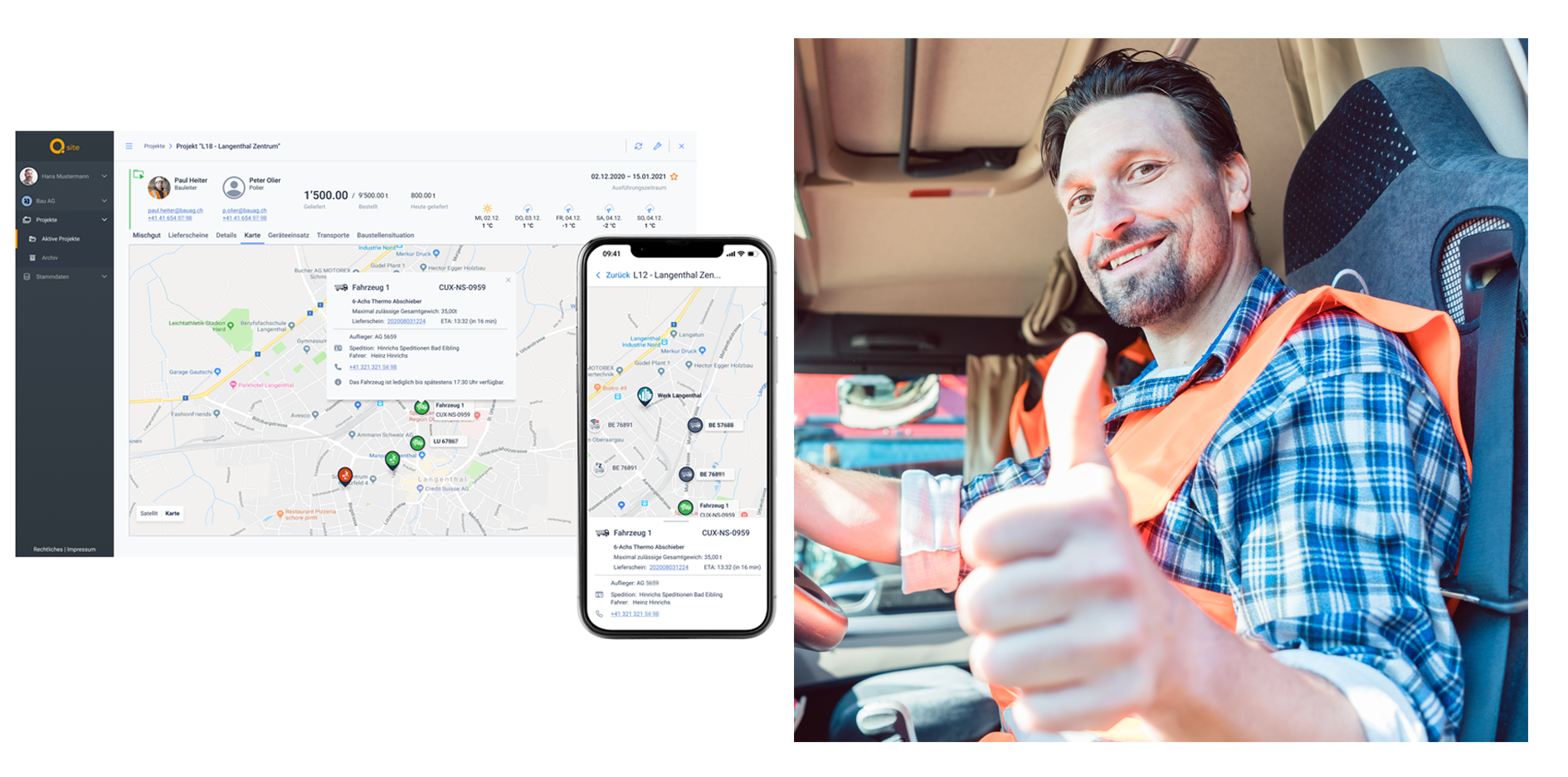

A central function of the connected construction site is to integrate logistics, specifically truck drivers with software solutions such as "Q Transport", directly into the paving process through their smartphones. During loading at the mixing plant, drivers receive not only the delivery note but also precise information about the planned route and the expected arrival time at the construction site. This real-time data enables drivers to carry out their transport tasks accurately and thus meet the logistics chain requirements as planned.

The live locations of the trucks are continuously transmitted to the construction company and the involved mixing plants. This ensures comprehensive transparency for all parties involved. Knowing the estimated arrival time at the plant enables efficient coordination of loading and dispatching. Delays and subsequent disruptions in delivery performance are avoided. Conversely, the scheduled loading intervals prevent premature loading and, as a result, excessive numbers of waiting trucks at the construction site.

The primary responsibility of the foreman on the construction site is to monitor and coordinate the ongoing paving work. To do this effectively, he needs reliable and up-to-date information about the project's progress. In this context, digital construction process support plays a crucial role. The mobile app "Q Site" provides the foreman with this information anytime and anywhere, in real time.

An example of such information includes the transmission of delivery notes from the asphalt plants and the associated quantity balances. These quantities, categorized as "Ordered," "In Transit," and "Already Paved," are continuously updated in real time. They provide the foreman and other decision-makers with the necessary insights to manage both the paving process and the supply chain. If discrepancies from the planned quantities arise, the system alerts the foreman, enabling quick adjustments to workflows. The digital assistant supports the foreman in identifying and addressing potential bottlenecks or issues early on.

Overall, this information and the resulting increased transparency enable the foreman to manage the paving process proactively and resource-efficiently, rather than merely reacting to unforeseen problems. Additionally, the software allows the site manager—and other involved parties—to view the current progress of the paving work anytime and from any location, enhancing the overall management of such construction projects.

Documentation and Evaluation

Systematic storage of process data ensures comprehensive documentation of the construction project. All relevant documents, including delivery notes for asphalt paving, are digitally archived, allowing for easy and quick access.

The thorough recording of asphalt transport processes provides transparent traceability. Every step in the transport process—from arrival at the mixing plant, through loading and arrival at the construction site, to unloading and return—is recorded in real time and digitally stored. These records form the basis for a detailed analysis of the logistics flow and the identification of bottlenecks.

Additionally, the paving process can also be precisely documented with solutions such as "Q Machines". This includes the paving positions of each delivery, the temperatures of the asphalt mix, the speed of the paver, and any downtime. If necessary, the recording of comprehensive compaction can also be added. This precise data contributes to quality assurance and allows for targeted improvements in future construction projects.

Document management also provides the capability to store various documents or photos related to the construction project or specific aspects of the paving process. In practice, this includes lab orders for samples, test reports, or photographic documentation of significant findings. Thus, all aspects of the construction project are thoroughly documented.

Productivity Improvements through Digital Construction Process Support

Digitalization and the associated end-to-end process support offer significant potential for asphalt road construction, while also introducing substantial changes for all stakeholders. Digital connectivity and support not only make asphalt paving more efficient but also significantly enhance quality and process adherence.

The introduction of digital collaboration platforms enables cross-company networking of the involved parties, which is considered a key factor for project success. Software solutions such as those from Q Point contribute significantly to this development. They provide comprehensive solutions for planning, monitoring, and documenting the construction process in real time. By replacing traditional communication methods with a reliable digital information flow in real time, all stakeholders benefit and form the foundation for process optimizations. These advancements are crucial for achieving sustainable productivity improvements and mark the shift from manual, craftsmanship-based methods to systematic and controllable processes.

Q Point | M.Pilger