The public sector is facing growing pressure: Infrastructure projects must be planned and implemented not only cost-effectively, but also sustainably and with careful use of resources. Today, clients in road construction demand more than ever a well-thought-out, digitally supported approach to project execution.

What’s required are precise planning, sustainable delivery and paving strategies, and end-to-end documentation - from the materials used to the environmental impact of the construction site. The digital transmission of delivery data and real-time information on paving and compaction processes has become key to achieving efficiency, transparency, and quality.

Creation of digitally supported paving, logistics, and quality plans, along with the use of tools for process optimization.

Use of connected machinery for automated monitoring and control of construction processes.

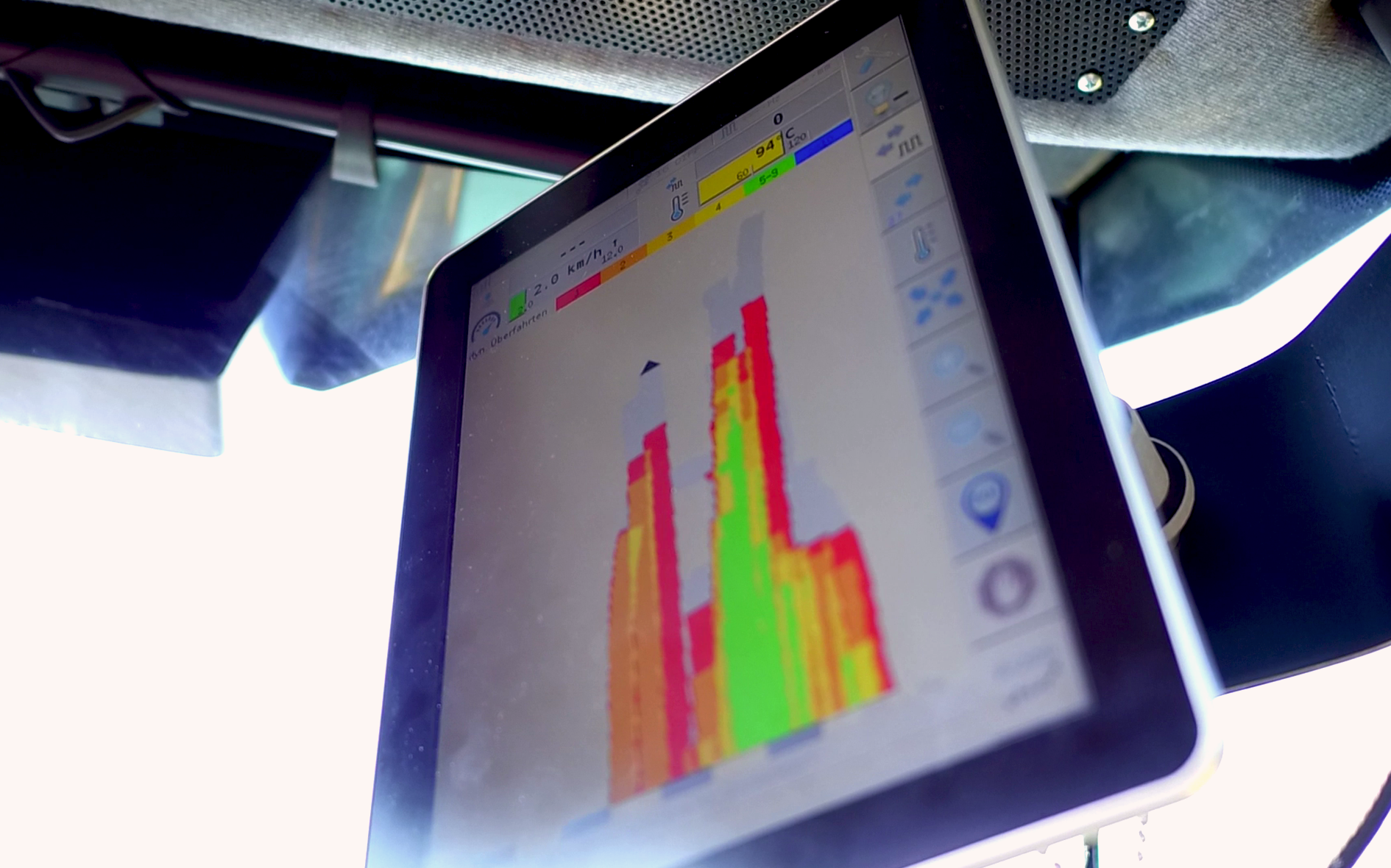

Continuous tracking of key paving parameters such as temperature and the number of rollers passes.

Complete digital logging of all process data for quality assurance and life cycle assessment.

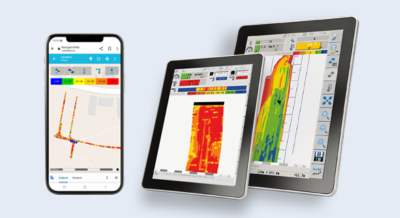

Use of mobile devices for monitoring, communication, and control. Integration into web-based systems for collaborative work.

Compliance with recognized digital standards in road construction and training of personnel in the use of new technologies.

Digital Solutions for Optimization

To meet these demands, more and more companies are turning to digital tools that enable precise control of construction processes. These solutions support the efficient coordination of construction projects, optimize resource use, and ensure seamless documentation. A fully connected network from site management to mixing plants and transport, ensures that relevant data is captured and shared in real time, enhancing transparency and collaboration across all stakeholders.

Efficient Construction Site Supply Through Digital Connectivity

Q Site Professional enables precise quantity determination based on construction plans and ensures demand-driven delivery scheduling. Automated progress monitoring helps detect deviations from the plan at an early stage. Clearly designed dashboards, reports, and comprehensive documentation meet the requirements of many public sector clients. A key advantage is the complete digital connectivity of all stakeholders, allowing for real-time capture and processing of all relevant data - for greater efficiency and transparency on the construction site.

Quality Control and Management with Connected Machines

Q Machines automatically captures relevant asphalt mix temperature data in real time on the roller and the paver. Additional measurements are recorded with precise positioning, centrally visualized, and enable transparent monitoring of compaction results. Comprehensive documentation ensures traceable installation quality at the highest level. Thanks to its manufacturer-independent system architecture, Q Machines can be seamlessly integrated into existing machine fleets, providing a centralized overview of the entire paving process, regardless of machine type.