DOPRASTAV a.s. is one of Slovakia’s leading construction companies and has long been synonymous with quality, precision, and innovation in road construction. The company also carries out international infrastructure projects. With a clear view of the future and a willingness to break new ground, DOPRASTAV is the first construction company to use the digital Q Machines system from Q Point on a construction site in the Czech Republic.

The pilot project was carried out on the D35 Janov-Opatovec motorway section. Two rollers and one asphalt paver were equipped with Q Machines technology. The system continuously records temperature, compaction, and position data, synchronizing them in real time across all connected machines. This creates a complete digital representation of the paving and compaction process - from the very first meter to the final pass.

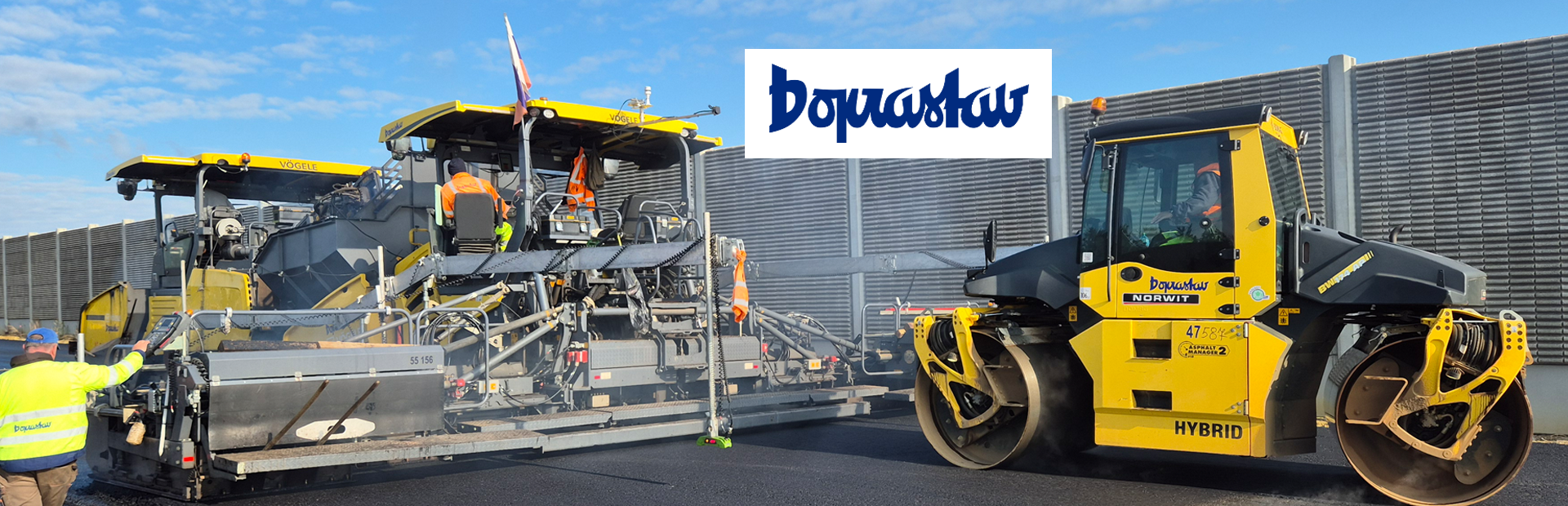

Paver equipped with the digital Q Machines system on the D35 highway.

Thanks to real-time information, site operations could be precisely coordinated, and unnecessary passes were avoided. This saves fuel, reduces CO₂ emissions, and ensures uniform compaction and optimal pavement quality - a clear benefit for both client and operator. The system’s ease of use and quick implementation convinced the construction team, and the new data transparency soon became an integral part of daily operations.

Sensors on the paver record real-time temperature and position data.

The successful pilot project on the D35 vividly demonstrates how digitalization, quality, and sustainability can go hand in hand in modern road construction. Thanks to this pilot project, DOPRASTAV is also ideally prepared if digital proof of the quality of the asphalt paving is required in the tender.

Connected rollers with the Q Machines system for digital compaction control.

DOPRASTAV is the first construction company to deploy Q Machines in a pilot project in the Czech Republic

Pilot project successfully completed on the D35 Janov-Opatovec motorway section

Two rollers and one paver digitally connected

Real-time data on temperature, compaction, and position

Fewer passes and continuous temperature and compaction monitoring = lower CO₂ emissions and longer asphalt lifespan

Digitalization as the foundation for greater transparency, quality, and sustainability